作为包装行业创新工具和服务的领先供应商,Saueressig 是 SGK 大家庭的一员,对我们的客户和同事每天面临的挑战有着深刻的理解。质量控制是我们作为一个行业努力实现持续创新的一个关键领域。我们可能处于游戏的巅峰状态,但 Saueressig 一直在努力做得更好,变得更好。

质量控制和印刷生产的挑战

印刷生产中没有出错的余地。打印工具和打印运行对任何客户来说都是一笔巨大的费用,因此消除错误的压力是巨大的。该工具必须与设计精确匹配,以避免与重新运行相关的成本。

直到最近,这意味着质量检查员还需要手动检查打印工具,以识别不匹配或损坏的情况。这种耗时的过程仍然是我们一些竞争对手的常见做法,而且 – 尽管承担任务的专业人员技能很高 – 不能保证准确性。质量控制是印刷生产过程中的关键时刻,可以成就或破坏印刷包装产品。我们的客户要求完美的结果,因此当新技术出现时,这个不精确的过程已经成熟,可以进行彻底改革。

挖掘 AI 在印刷质量控制方面的潜力

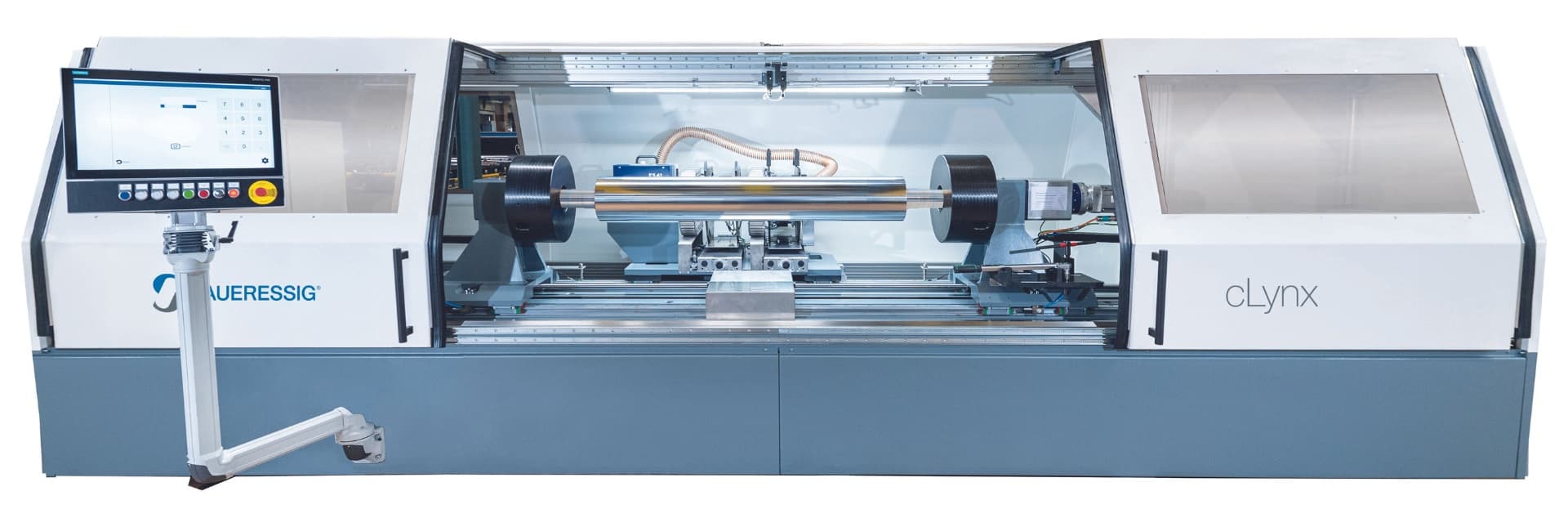

在 2010 年代,虽然人工智能仍然只是一个流行词,但 Saueressig 发现了一个利用创新来改变印版检测的机会。cLynx 于 2016 年推出,是印刷生产中首个由 AI 驱动的 QC 技术。

cLynx 将检查打印工具的过程数字化,完全消除了手动质量检查的需要。该工具对微米级错配进行数字分析,可以在单个文件上找到数千个,每个文件都在 0.01 毫米到 0.05 毫米之间。然后,它建立一个数字模型,合理化发现的错误以提高用户友好性。cLynx 将任何不相关的故障(例如可能是灰尘)与相关故障区分开来。最终结果:QI 能够轻松看到真正的错误,从而快速简单地确定必要的行动,从而保证完美的结果。

在实践中学习

cLynx 边做边学。自发布以来,我们一直在监督构建潜在不匹配目录的过程,这为我们开发软件提供了支持。我们开发了一种扫描仪,它可以直接从打印工具而不是打印样本中获取图像,并且 AI 工具会了解不同之处。

cLynx 产品引领国际市场 – 这要归功于 Saueressig 声称尽早利用 AI 的领先优势,以及我们在开发 AI 以满足客户需求方面的经验和专业知识。

印刷生产的未来

随着 AI 在印刷生产质量检测中的快速改进和利用,这一速度继续加快。该工艺的好处是巨大的:对客户来说,检测和处理成本最低,节省了生产时间,内部改进的工作流程计划大大提高了生产力。印刷生产的未来无疑将纳入 AI 的发展,而 Saueressig 将处于这个印刷新时代的最前沿。

关于 Ingo Beutler

Ingo Beutler has been part of the print and media industry for more than 3 decades in various positions. After his first professional station as a media designer, he had the opportunity to share his experience in the print and media industry in leading positions at different companies. After being responsible for the entire prepress-business within the SAUERESSIG Group, Ingo Beutler is now in charge of digitisation at the SAUERESSIG Group. There he develops new applications for external and internal use with his team in order to create the entire process from design to printing more efficient and contemporary.

关于 Dr. Daniel Schmidt

Daniel Schmidt is a visionary leader in the field of computer vision and artificial intelligence, having embarked on his journey a decade ago with a groundbreaking student project aimed at enhancing the quality of rotogravure cylinders. His innovative approach not only revolutionized the production process but also significantly reduced costs, paving the way for substantial advancements in the industry. Since earning his PhD in Innovation and Economics, Daniel has successfully spearheaded numerous automation projects that have further propelled his company into the future of manufacturing. Daniel’s passion for innovation is matched only by his commitment to driving meaningful change, making him an invaluable asset to his team and the industry at large. His philosophy: “Innovation is not just about technology; it’s about transforming ideas into impactful realities.”